Our Blog

Categories

- Recycling Technology

- Sustainability

- Industry Insights

- Corporate Responsibility

- Innovations

Recent Posts

Subscribe

Stay updated with our latest blogs and news.

The Rise of Rotomoulding and Plastic Recycling in India

The Rise of Rotomoulding and Plastic Recycling in India

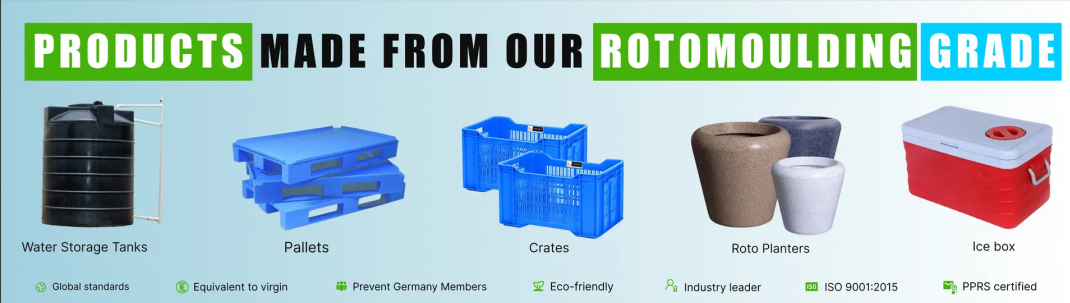

India is emerging as a global leader in the rotomolding industry and plastic recycling, driven by innovation, sustainability, and the growing demand for durable plastic products. Rotomolding, or rotational molding, is a versatile manufacturing process used to produce hollow plastic items such as tanks, drums, and containers. Coupled with advancements in recycling technology, Indian manufacturers are paving the way for eco-friendly solutions in the plastics sector.

Rotomoulding Powder: The Backbone of the Industry

Rotomoulding powder plays a critical role in this industry. Manufacturers across India specialize in producing high-quality powders like LLDPE rotomolding powder, which is known for its durability, flexibility, and resistance to environmental stress. These powders are essential for creating products such as water tanks and industrial hoppers. Leading suppliers provide powders in various grades, including HDPE granules for drums and crates, PP granules for paint pails, and LDPE recycled granules film grade.

The demand for rotomolding powder is increasing due to its applications in diverse sectors like construction, automotive, and agriculture. With cities like Ahmedabad and Bengaluru hosting top manufacturers, India has become a hub for innovative rotomolding solutions.

Sustainability Through Plastic Recycling

Plastic recycling is at the heart of India's waste management strategy. Companies are focusing on producing recycled granules such as HDPE recycled granules for crates and PP recycled granules. These materials not only reduce plastic waste but also offer cost-effective alternatives to virgin polymers. The recycling process involves converting discarded plastics into reusable materials like PPCP granules and LDPE film-grade granules.

India's recycling rates are improving, yet challenges persist. According to reports, only 12% of plastic waste undergoes mechanical recycling. To address this issue, top recycling companies are integrating informal sectors into formal systems to enhance collection and processing efficiency.

Pioneers in Rotomolding and Recycling

India boasts several pioneers in the rotomolding industry who have revolutionized manufacturing techniques. These innovators have introduced advanced technologies that enhance product quality while minimizing environmental impact. For instance, rotomolding plastics are now used to manufacture electric vehicle components, outdoor furniture, and playground equipment.

Similarly, top recycling companies like Gravita India are setting benchmarks by expanding their operations into diverse materials such as rubber and lithium while maintaining eco-friendly practices. Their efforts contribute significantly to reducing carbon emissions and promoting sustainable development.

Applications and Innovations

Rotomolding has diverse applications ranging from water tanks to industrial containers. The process allows manufacturers to create complex shapes without seams or joints, ensuring durability and leak-proof designs. Products like HDPE granules for 200-liter drums and PP granules for paint pails showcase the versatility of this technique.

In the recycling domain, innovations such as EPR (Extended Producer Responsibility) compliance are transforming waste management practices. Companies are adopting EPR credits to ensure proper disposal of plastic waste while meeting regulatory standards.

Challenges in Plastic Waste Management

Despite advancements, India's plastic waste management faces hurdles. A significant portion of waste remains unaccounted for due to inadequate collection systems. Informal sectors play a vital role but lack resources to scale operations effectively. To overcome these challenges, policymakers must prioritize integrating informal recyclers into formal frameworks and incentivizing sustainable practices.

Future Prospects

The future of rotomolding and plastic recycling in India looks promising. With an annual growth rate of 20% in the rotomolding sector, manufacturers are poised to meet increasing demand for durable plastic products. Recycling initiatives will further support this growth by providing eco-friendly raw materials.

As awareness about sustainability grows among consumers and industries alike, India is set to become a global leader in environmentally responsible manufacturing practices.

For more information on sustainable plastics solutions, visit Recycle Plastics.